Celebrating 30 Years of Astropol: A Story of Innovation and Sustainability

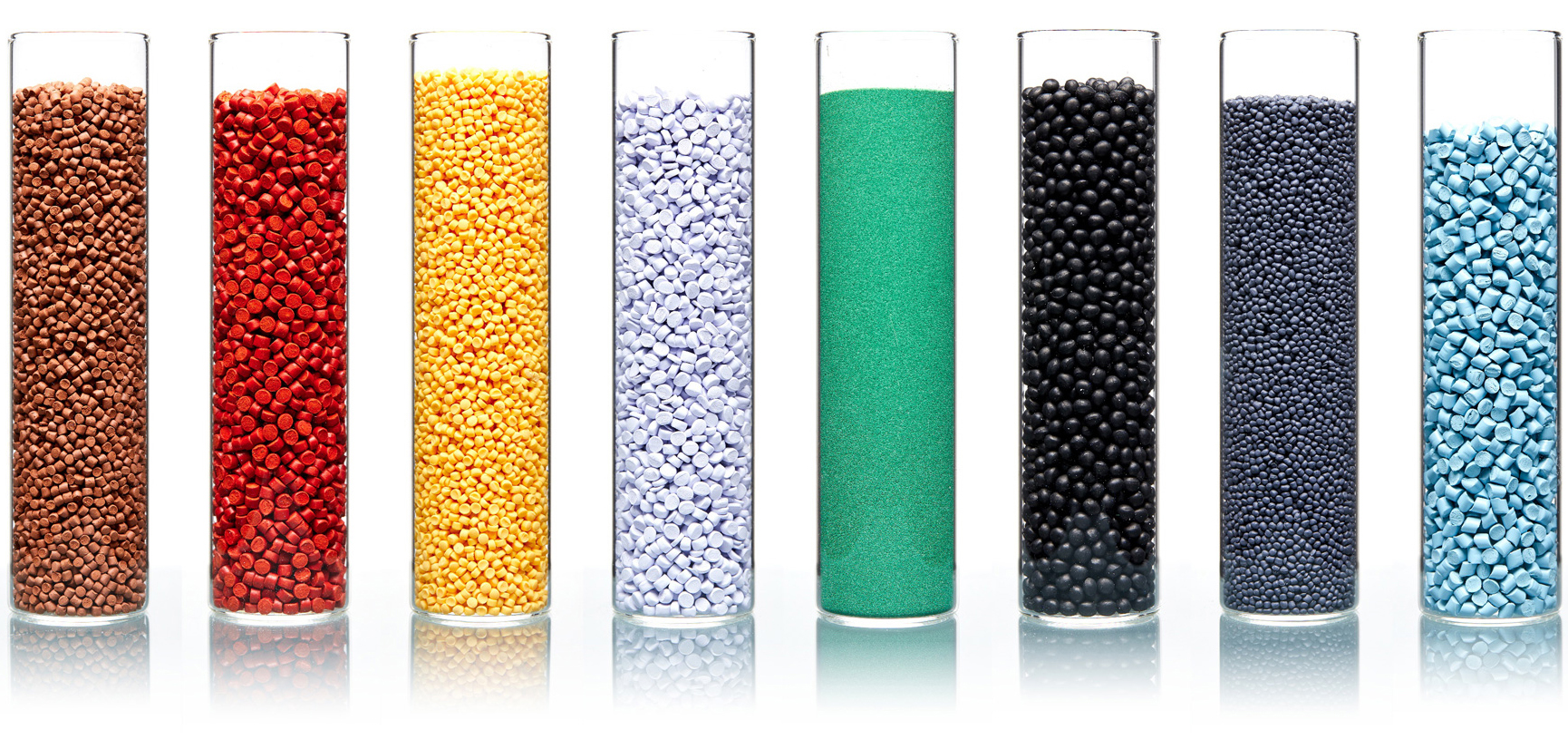

This year marks a significant milestone for Astropol, a leading manufacturer of bespoke colour and additive masterbatches for the plastics processing industry. We’re thrilled to be celebrating our 30th anniversary, and to take this opportunity to share our story with you.

From Humble Beginnings to Industry Leadership

Astropol’s journey began in 1994, founded by Brian French with a vision to address the challenge of plastic waste. Recognising the potential of recycled PVC plastic, French established the company to re-compound and revitalise this material, a practice that is now commonplace in today’s circular economy.

While initial limitations led to a strategic shift, French’s innovative spirit and understanding of the market led him to focus on producing PVC-based colour and additive masterbatches. This marked the beginning of Astropol’s specialization in bespoke solutions for the PVC processing industry, laying the foundation for our future growth.

A Team Effort: Innovation and Expertise

The arrival of Brian Hughes in the mid-90s brought extensive technical and commercial expertise to the table. Together with French, they steered the company towards bespoke PVC masterbatches, initially targeting the flexible PVC market. Their product offering soon expanded to encompass a wider range of applications.

Following French’s passing, Brian Hughes, along with his business partner Patricia Gotheridge, acquired Astropol. Under Hughes’ leadership, the company expanded its focus to include the rigid PVC market, developing innovative masterbatches for window profiles and pipe extrusion.

In 2001, Chris Wright, a fellow graduate chemist, joined Astropol. Combined with Hughes, Wright’s expertise and vision further strengthened the company’s technical capabilities and market reach within the rigid PVC sector. His contributions significantly impacted Astropol’s growth, culminating in his management buyout in 2008.

Looking to the Future: Sustainability and Growth

Since then, Astropol has witnessed significant growth, investing in production capacity, expanding its facilities, and building a team of highly skilled professionals. This dedication has solidified our position as a leading supplier of bespoke colour and additive masterbatches, both in the UK and internationally.

Our commitment to innovation extends beyond PVC. In 2018, we diversified our offerings to include bespoke masterbatches for all commodity and engineering polymer applications. This move reflects our focus on partnerships, technical competency, and exceptional service, ensuring we remain at the forefront of the ever-evolving plastics industry.

As Astropol celebrates its 30th anniversary, we look to the future with unwavering dedication to sustainable practices, technical excellence, partnerships and service exceeding customer expectations. We’re excited for what the next chapter holds, and we thank you for being a part of our journey.